English

French

Polish

Portuguese

Spanish

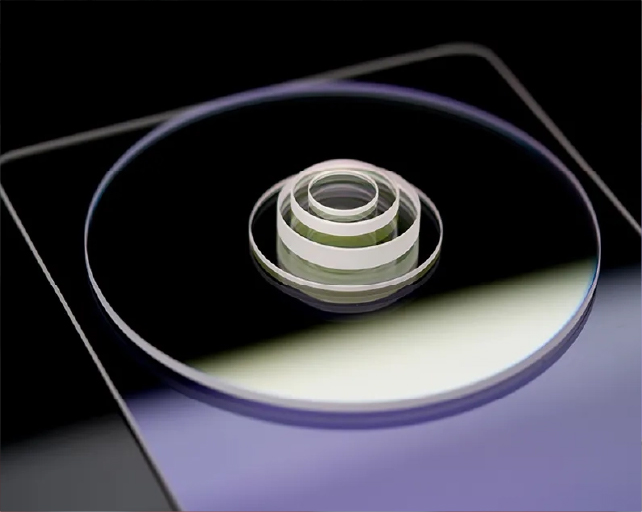

A fiber laser cutting machine is a metal cutting device that uses a fiber laser as its core light source. It couples the laser beam into an optical fiber for transmission, then focuses the beam into a high-energy-density spot through a focusing lens. The spot acts on the metal surface to instantly melt and vaporize the material, and the molten slag is blown away with auxiliary gases (such as nitrogen and oxygen) to achieve high-precision cutting.

Equipped with world-class laser sources and precision gear rack drives, the machine delivers positional accuracy up to ±0.01mm and repeatability of 0.02mm. Minimal heat-affected zone (HAZ) ensures no material deformation, with smooth, burr-free edges that eliminate post-processing.

Cutting speed reaches up to 215m/min for thin sheets, with electro-optical conversion efficiency much higher than traditional cutting technologies. 30% energy saving compared to plasma cutters, and low maintenance requirements reduce long-term operational costs.

Industrial-grade welded bed with internal stiffeners ensures no deformation for 10+ years. Supports cutting carbon steel (up to 40mm), stainless steel (up to 15mm), aluminum, copper, and other metals. Available in custom sizes (3000×1500mm to 6000×2500mm) to meet diverse needs.

| Category | Common Sizes | Material | Power Range |

|---|---|---|---|

| Small | 20–25.4 mm | JGS1 / JGS2 | 1.5–6 kW |

| Medium | 27.9–38.1 mm | JGS1 / JGS2 | 6–20 kW |

| Large | 40–55 mm | JGS1 / JGS2 | 15–30 kW |

| Extra Large | 60–150 mm | JGS1 / JGS2 | 30 kW+ |